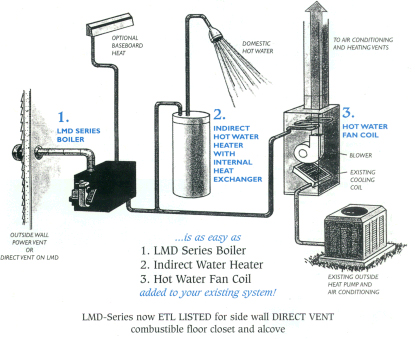

LMD DIRECT VENT SERIES PACKAGED LOW MASS STEEL BOILERS

The LMD Boiler is your answer to costly and ineffective ELECTRIC HEAT. With its compact design, the LMD can be installed in a space as small as a closet.

LARGER CAPACITIES- The LM 100/125 boiler is available for larger capacities. It features blended firing rates of 1.00, 1.10 and 1.25 GPH.

- DESIGN – A wet-base design, a horizontal tube, and a two-pass heat exchanger makes this one of the best-designed, best-heating boilers on the market.

- Swing Out burner door

- LOW WATER – content provides heat or hot water delivery within minutes of start-up.

- The compatibility with indirect storage tanks provides enough hot water to meet the comfort requirement of virtually any home.

- ONE-PIECE CONSTRUCTION – ensures years of trouble-free service. There are no push nipples or “O” rings to lea

- COMPACT DESIGN – saves space, yet it’s capable of three firing rates.

- EXPENSES – We reduce servicing expenses by making the heat exchanger easily accessible from either end.

RATING – The 86.0% AFUE rating is among the highest from today’s boilers.

As with all of our boilers, the low mass boiler is manufactured in the USA with American-made steel, constructed to ASME code requirements passing rigorous third-party inspections and hydrostatic tests and is backed by a lifetime limited warranty.

- WATER VOLUME- The low, 5-1/2 gallon water content provides heat and hot water delivery within minutes of start up. The low mass concept reduces standby losses associated with boilers during off cycles and provides nearly instant heating with less fuel consumption.

EFFICIENCY – 86.0% TO 86.4% AFUE- The high efficiency obtained with the LM boiler are due to the design to the heat exchanger, a two pass, wet base, Scotch Marine design.

MULTIPLE FIRING RATES – .75 TO .85- One boiler can be fired at two different rates, offering versatility and keeping costs low. Each unit is supplied with nozzles and labels for all two rates.

- FORCED DRAFT- Forced draft chimney design performs with marginal chimney draft, assuring proper combustion in spite of poor chimneys.

- COMPACT SIZE- Standing 19-3/4 inches high, 19 inches wide, and 36 inches long, this compact boiler not only saves space but can easily be installed in areas not approved for other boilers. The LM series is approved for both closet and alcove installation on combustible flooring.

ASME CONSTRUCTED – Each boiler is constructed and hydrostatically tested in accordance with ASME Boiler Code.

Standard Features

| ASME Code Boiler | National Board Stamped |

| Flush Jacket | Burner "Quick Disconnect" with swing door |

| Ceramic Fiber Combustion Chamber | GeniSys Control (Beckett) |

| Altitude, Temperature & Pressure Gauge | Aquasmart Control or Hydrolevel Control |

| ASME Relief Valve | Auxiliary High Limit with Manual Reset |

| Built-In "Air Scoop" | 007 or Equivalent Circulator (not mounted) |

| Brass Boiler Drain | Factory Assembled, Wired and Packaged |

| ETL Listed | Air Intake Attachment |

| Optional Equipment | |

| Bronze Circulator | Boiler Stand |

| Thermostatic Bypass Valve | |

Specifications

| Blended Sizes | LM/LMD 75/85 | LM/LMD 100/110/125 | |||

|---|---|---|---|---|---|

| Model Designation | LM/LMD 75 | LM/LMD 85 | LM/LMD 100 | LM/LMD 110 | LM/LMD 125 |

| Input BTU/HR | 105,000 | 119,000 | 140,000 | 154,000 | 175,000 |

| Heating Capacity BTU/HR | 91,000 | 102,000 | 121,000 | 133,000 | 151,000 |

| Net Rating BTU/HR | 79,000 | 89,000 | 105,000 | 115,000 | 131,000 |

| Input #2 Oil GPH | 0.75 | 0.85 | 1.00 | 1.10 | 1.25 |

| Boiler Draft Loss Inches | 0 - +1.0 | 0 - +1.0 | 0 - +1.0 | 0 - +1.0 | 0 - +1.0 |

| Water Content | 5.5 GAL | 5.5 GAL | 8 GAL | 8 GAL | 8 GAL |

| Boiler Height w/Control | 25" | 25" | 25" | 25" | 25" |

| Jacket Width | 19 ⅛" | 19 ⅛" | 19 ⅛" | 19 ⅛" | 19 ⅛" |

| Hydronic Supply Height | 20 ½" | 20 ½" | 20 ½" | 20 ½" | 20 ½" |

| Burner Height | 9 ⅜" | 9 ⅜" | 9 ⅜" | 9 ⅜" | 9 ⅜" |

| Hydronic Return Height | 5" | 5" | 5" | 5" | 5" |

| Flue Outlet Diameter | 5" | 5" | 5" | 5" | 5" |

| *A = Jacket Depth | 25 ½" | 25 ½" | 35" | 35" | 35" |

| Return Height | 5" | 5" | 5" | 5" | 5" |

| Hydronic Supply Size | 1 ¼” | 1 ¼” | 1 ¼” | 1 ¼” | 1 ¼” |

| Hydronic Return Size | 1 ¼” | 1 ¼” | 1 ¼” | 1 ¼” | 1 ¼” |

| DOE AFUE Rating | 86.2% | 86.0% | 86.4% | 86.2% | 86.0% |

| Shipping Weight (lbs) | 350# | 350# | 440# | 440# | 440# |

| * For LMD Series add 10lbs to weight | |||||

All appliance designs are forced draft pressure fired for optimum performance. They are available with either Beckett, Carlin, or Riello oil burner.

Vent Kits

| THERMO-VENT 175 Vent Kits One per boiler required. One wall opening required. | Part No. | Shipping Weight (pounds) |

|---|---|---|

| TV-175 Combination Vent Kit - 10ft | 281072 | 24 |

| TV-175 Combination Vent Kit - 15ft | 281082 | 30 |

| TV-175 Combination Vent Kit - 20ft | 281093 | 36 |

| * Note: Vent Hood Packaged Separately from Tubing. (2-cartons) 4" tubing shipped inside of 5" tubing. | ||