Dry Base – S Series Oil Boiler

The popular S-Series Boilers are dependable, economical and budget-priced.

Designed, constructed and hydrostatically tested in accordance with The American Society of Mechanical Engineers Boiler Code Section IV and is pressure tested by an independent inspection agency prior to final assembly.

FIRING RATE 0.85 to 1.35 GPH – Allows the installer to size the boiler more closely to the home heating needs for greater efficiency. The lowest firing rate, 0.85-89,000 BTU, is necessary for many well insulated homes where the heat loss is minimal.

- COMBUSTION CHAMBER – 1″ thick pyrolite ceramic fiber material. Fast warm-up – glows to incandescence in 11-17 seconds. Large diameter allows brushing flue passages without punching through chamber.

- PUMP PRESSURE – The S-Series operates at 140 PSI pump pressure for better fuel atomization, thereby having the ability to tolerate fuel oil with heavy ends.

- IGNITION SYSTEM – The S-Series is standard with a state-of-the-art, solid state ignition system, making it more tolerant to low voltage or voltage fluctuations.

- ELECTRONIC DELAY with Solenoid Valve “clean-cut” Fuel Pump.

- WATER CONTENT – Compared to other dry base boilers, the S-Series has exceptional water content. The first size has 16 gallons of water. High water volume and placement of the coil in the hottest part of the boiler allows for maximum coil performance.

- EFFICIENCIES UP TO 86.2% AFUE – The unique tube design of the S-Series boiler heat exchanger slows the flue gases, allowing for more effective heat transfer without the need for extreme baffling often seen in other vertical tube boilers.

- STANDARD FEATURES- The following built-in features found in all Thermo-Dynamics boilers increase the longevity of the boiler and make the unit easier to service, ensuring maximum efficiency and performance for the life of the boiler.

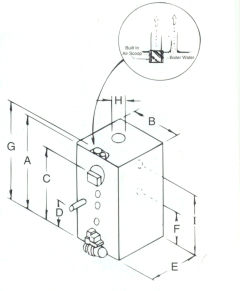

- BUILT-IN “AIR SCOOP” – purges air from the system providing a quiet, trouble free hot water heating system without the use of external devices.

- EXTENDED FLANGE COIL – is away from the boiler for easy accessibility. The use of ribbed neck carriage bolts eliminates the problems encountered when a weld stud is broken during servicing. The large coil plate allows for a greater gasket sealing area.

- EASY CLEANING – and maintenance accessibility to combustion areas and the open tubes make it easy for the service technician to thoroughly clean the boiler. No tight, pin-type passage ways with “hidden nooks and crannies”, making a thorough cleaning impossible. A well-maintained boiler continues to perform at higher efficiency and is less likely to develop service problems.

Standard Features

- EXTENDED COIL FLANGE – Provides dependable operation while assuring easy servicing.

- TOP FLUE CONNECTION – Makes installation easy and simplifies annual servicing.

- OVAL TUBE DESIGN – Makes possible the most efficient utilization of fuel, production of central heat and domestic hot water with the most economical transfer of energy.

- COPPER DOMESTIC HOT WATER COIL – Provides the hot water you need when it is needed. The cost of a separate domestic hot water system is eliminated.

- COMBUSTION CHAMBER – Ceramic fiber combustion chamber utilizes space age materials technology and is uniquely designed to effect a tight seal with the heat exchanger. Chamber is easily serviced from front of the unit.

- ASME CONSTRUCTION – Designed, constructed and hydrostatically tested in accordance with the American Society of Mechanical Engineers Boiler Code Section IV.

| ASME Code Boiler | Built-in Air Trap |

| Insulated Flush Jacket | National Board Stamped |

| Ceramic Fiber Combustion Chamber | 007 or Equivalent Circulator (mounted) |

| Altitude, Temperature & Pressure Gauge | Brass Boiler Drain Valve |

| ASME Relief Valve | Factory Assembled, Wired and Packaged |

| Tankless Domestic Hot Water | Aquasmart Control or HydroLevel 3250 Control |

| GeniSys Control (Beckett) | Oil Vent Damper Included |

| **Note: S-125/135 package boilers shipped w/2-nozzles/firing rate - 1.25 GPH nozzle installed at factory. | |

Specifications

All appliance designs are forced draft pressure fired for optimum performance. They are available with either Beckett, Carlin, or Riello oil burner.

| MODELS | S 85 EE | S 100 EE | S 110 EE | S 125 EE | S 135 EE |

|---|---|---|---|---|---|

| IBR Firing Rate GPH (max) | .85 | 1.00 | 1.10 | 1.25 | 1.35 |

| Nozzle Size | .65 x 80B | .75 x 80B | .85 x 80B | 1.00 x 80A | 1.10 x 80A |

| IBR Input (BTU/HR) | 119,000 | 140,000 | 154,000 | 175,000 | 189,000 |

| IBR Heating Capacity (BTU/HR)* | 102,000 | 120,000 | 132,000 | 151,000 | 163,000 |

| IBR Net Rating (BTU/HR) | 89,000 | 105,000 | 115,000 | 131,000 | 141,000 |

| Chimney Size | 8x8x15 | 8x8x15 | 8x8x15 | 8x8x15 | 8x8x15 |

| Draft Over Fire (Negative) | -.02 | -.02 | -.02 | -.02 | -.02 |

| Water Content (gal) | 16 | 15½ | 15 | 14 | 14 |

| Domestic Coil Capacity** | 3 or 5 | 3 or 5 | 3 or 5 | 3 or 5 | 3 or 5 |

| A-Jacket Height | 38 ½" | 38 ½" | 38 ½" | 38 ½" | 38 ½" |

| B-Jacket Width | 21 ¼" | 21 ¼" | 21 ¼" | 21 ¼" | 21 ¼" |

| C-Coil Supply Height | 31 ½" | 31 ½" | 31 ½" | 31 ½" | 31 ½" |

| D- Hydronic Return Height | 22" | 22" | 22" | 22" | 22" |

| E-Jacket Length | 21 ¼" | 21 ¼" | 21 ¼" | 21 ¼" | 21 ¼" |

| F-Alt. Hydronic Return | 22" | 22" | 22" | 22" | 22" |

| G-Hydronic Supply Height | 36" | 36" | 36" | 36" | 36" |

| H-Flue Pipe Diameter | 6" | 6" | 6" | 6" | 6" |

| I-Relief Valve Height | 33 ½" | 33 ½" | 33 ½" | 33 ½" | 33 ½" |

| Shipping Weight | 320 | 325 | 330 | 345 | 350 |

| Hydronic Supply Tapping | 1 ¼" | 1 ¼" | 1 ¼" | 1 ¼" | 1 ¼" |

| Hydronic Return Tappings | 2-1 ¼" | 2-1 ¼" | 2-1 ¼" | 2-1 ¼" | 2-1 ¼" |

| AFUE*** | 86.0 | 86.0 | 86.0 | 86.2 | 86.0 |

| * Based on DOE Test Procedures | |||||

| ** Coil capacity based on 5 minute draw 5 minute waiting period | |||||

| *** Based on unit installed with 6" Oil Vent Damper Supplied | |||||